CFOAM® is a new structural material, made from coal in a cost-effective proprietary process, which is inexpensive, lightweight, fire-resistant, impact absorbing, can be thermally insulating or conducting, and whose electrical resistivity can be varied over nine orders of magnitude.

CFOAM®

This versatile, next-generation material has been under development since 1998, with both internal funding and funding made available through several SBIR program awards.

During this period, manufacturing processes have been refined and extensive testing has been conducted to characterize the material’s unique properties.

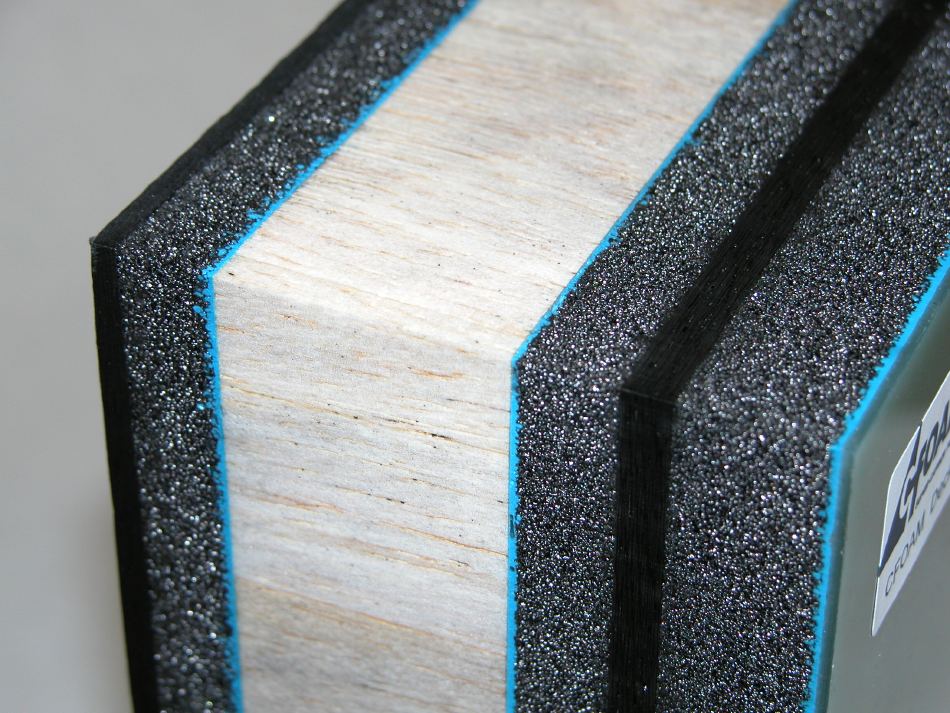

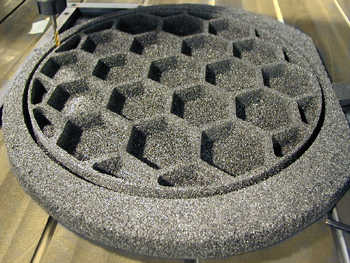

CFOAM® has been produced in a variety of forms from thin sheets to near-net-shape 3D components. The material can be cut, milled, turned, etc. with conventional equipment and tooling.

CFOAM® can accommodate metalized coatings using flame-spray techniques, allowing fasteners to be readily attached. Integration with other materials including impregnation with phenolic or other resins, and lamination with Kevlar™, phenolic-resins, or other laminates is straight forward, again using commercially available equipment.

CFOAM® is the enabling technology for a host of

next-generation material systems and components,

replacing those currently based on more conventional materials.

If you would like to know more about CFOAM® please visit our website at www.cfoam.com.