It has been a goal of Touchstone Research to fill the void left by the loss of the many US steel R&D facilities.

Steel Research & Development

For nearly three decades, Touchstone Research Laboratory has been involved in steel research and steel product development.

For nearly three decades, Touchstone Research Laboratory has been involved in steel research and steel product development.

During the first half of the 20th century the largest producing steel companies in the US, including National Steel, US Steel, Weirton Steel, and Wheeling-Pittsburgh Steel, maintained their own R&D centers with world class research facilities and a large number of researchers. However, during the second half of the 20th century these companies began to divest their R&D centers in order to cut their operating costs.

In 1994 Touchstone absorbed into its laboratory most of the capabilities from the research facility of the 7th largest US steel producer at the time, Wheeling-Pittsburgh Steel.

It has been a goal of Touchstone Research to fill the void left by the loss of the many US steel R&D facilities. Some of the R&D tasks performed by Touchstone Research Laboratory include research related to the development of steel products, failure analysis, warranty evaluations, and quality control testing for the steel industry.

It has been a goal of Touchstone Research to fill the void left by the loss of the many US steel R&D facilities. Some of the R&D tasks performed by Touchstone Research Laboratory include research related to the development of steel products, failure analysis, warranty evaluations, and quality control testing for the steel industry.

Touchstone is uniquely positioned to take up R&D projects of interest to steel producers and users of steel. Standard research capabilities available at Touchstone are as follows:

- Chemistry laboratory equipped with an Inductively Coupled Plasma (ICP).

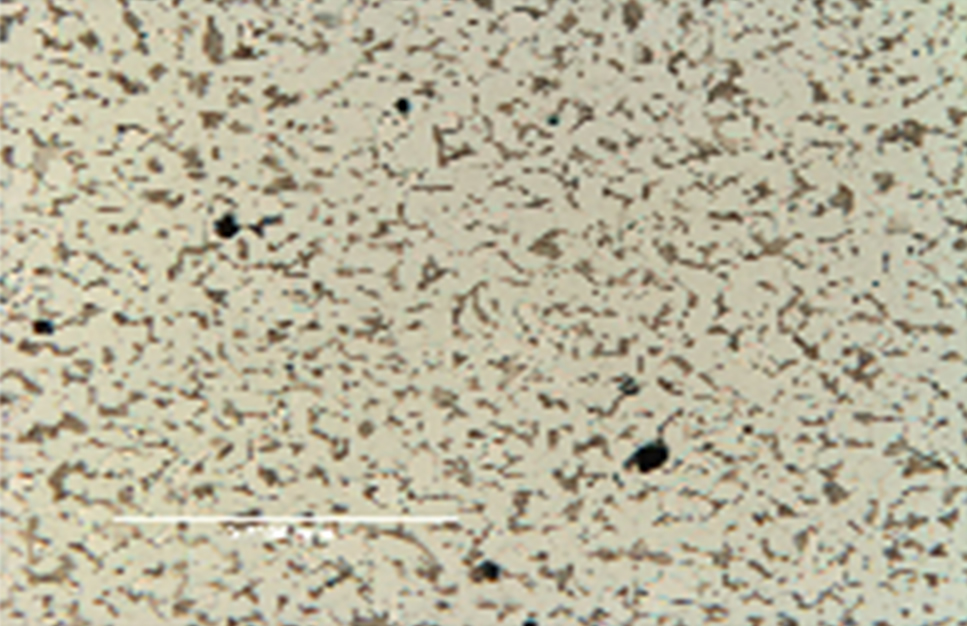

- Light microscope for optical metallography.

- Three Scanning Electron Microscopes (SEM) with thin window energy dispersive spectrometer (EDS).

- A microstructural analysis laboratory equipped with a metallograph with a wide range of imaging such as bright field, dark field, Nomarski illumination, oblique illumination and image analysis.

- Numerous mechanical testing frames to perform a wide range of mechanical tests including tension, compression, fatigue, fracture toughness, cryogenic and elevated temperature; hardness testers; and Olsen cup tester for evaluating formability of sheet metal.

- Corrosion test facilities (salt fog ASTM Designation: B 117, SWAAT, CASS and others).

- Heat treatment furnaces for experimental purposes.

- A machine shop with manual and CNC equipment, including lathes, vertical mills, 5-axis CNC mill, and a large bed 5-axis CNC router.

Touchstone has participated in R&D projects related to stainless steel cut nails, galvanized steel culvert, and steel building materials. Quality control tests include mechanical testing and accelerated testing of organic and inorganic coatings on steel panels.

Please give us a call for a no-cost assessment of your project needs.