As the world moves toward lighter, more efficient, more responsive vehicles new, lightweight materials like carbon fiber composites become a bigger part of design.

Exhaust Systems

As the world moves toward lighter, more efficient, more responsive vehicles new, lightweight materials like carbon fiber composites become a bigger part of design.

As the world moves toward lighter, more efficient, more responsive vehicles new, lightweight materials like carbon fiber composites become a bigger part of design.

While composites are wonderful for lightweight, strong structures, virtually none are high temperature – leaving engine compartments and exhaust system mostly made from high density, and therefore heavy metal parts.

Among the R&D programs at Touchstone is the development of a new set of non-metallic designs utilizing a set of materials which were almost unavailable just a few years ago.

The creation of non-metallic exhaust systems stemmed out of the development of a new carbon foam at Touchstone made from coal, CFOAM®, which was thought to be the answer to a new, high temperature core in composite sandwich structures.

CFOAM carbon foam can be used indefinitely to about 650°F (343°C).

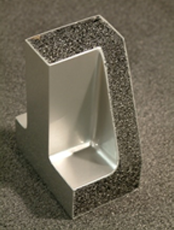

Utilizing CFOAM carbon foam with ceramic matrix composites and polymer composites, Touchstone has developed a set of unique designs to handle the exhaust from internal combustion engines, and turbine engines.

The ceramic matrix composites Touchstone is utilizing will operate at temperatures up to 3600°F (2000°C) and the polymer composite systems will operate up to about 450°F (232°C).

Lightweight, non-metallic exhaust systems can provide higher engine operating efficiencies, improved handling of high performance automobiles and boats, and opens the design envelope to manufacture designs difficult with typical metal designs.

For example, imagine a composite cowling where the exhaust system is integral in the aerodynamic design of the engine cowling and where the shape of the exhaust can be designed without the preconceived notion that the exhaust system will always be circular in cross section.

Touchstone has all the equipment and expertise to develop these non-metallic exhaust systems, from its host of materials engineers, to its engine test stand to its CNC mills to its, 36 foot long autoclave.

For more information about this new technology, please call or email us.